Ohjausyksiköt

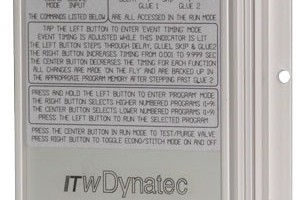

TPC-9™ Sarja

The TPC-9 Pattern Controller from ITW Dynatec, used in conjunction with your hot melt adhesive applicator, accurately controls glue output for reduced waste and more consistent output. Users can program a custom pattern with up to two glue events or simply choose the economy mode feature that automatically creates a skip of 30 or 50%. Both utilize adhesive more efficiently while still ensuring a strong bond, and the TPC-9 also gives you the flexibility to store up to 9 programs of different settings.

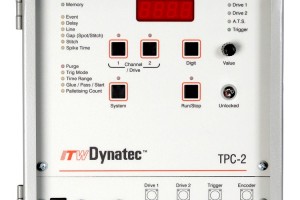

TPC-2™ Sarja

The TPC-2 from ITW Dynatec is a time-based adhesive pattern controller ideal for tracking and applying adhesive patterns on fixed speed production lines. The TPC-2 is dual channel and has permanent memory storage for up to 4 programs for varying application requirements. Fine-tuning of patterns can be performed on-the-fly to keep production running smoothly.

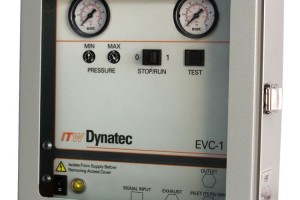

EVC-1™

The EVC-1 (Electronic Volume Controller) from ITW Dynatec provides superior technology for varying adhesive volume during parent machine line speed changes.

DY 2002™ Sarja

Liimauksenohjausyksiköt

DY 2008™ Sarja

DY2008 on monikanavainen ohjausyksikkö jolla voidaan hallita kuuma- ja kylmäliimausventtiileitä. Laitteistoni muistiin voidaan tallettaa tiedot 60 tuotteelle. Ohjausyksikkö osaa säätää venttiilin avaus ja sulku viiveen sekä liimamäärän ratanopeuden mukaan.

DPC-2™ Sarja

The DPC-2 from ITW Dynatec is a distance-based adhesive pattern controller ideal for tracking and applying adhesive patterns on packaging lines with frequent line speed changes. The DPC-2 is dual channel and has permanent memory storage for up to 4 programs for varying application requirements. Fine-tuning of patterns can be performed on-the-fly to keep production running smoothly.

DynaControl V6

ITW Dynatec’s Dynacontrol V6 is a modular control platform that serves as the next generation of globally standardized software and hardware for Dynamelt ASUs.