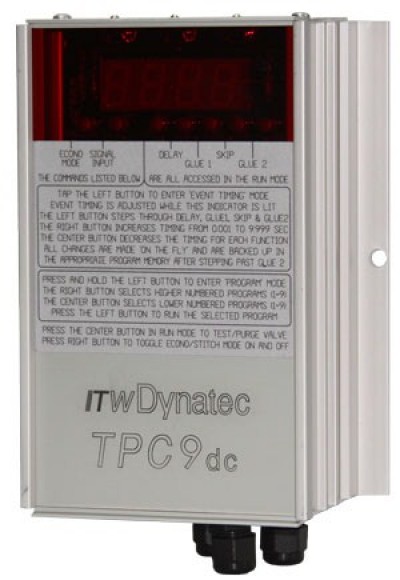

TPC-9™ Sarja

The TPC-9 Pattern Controller from ITW Dynatec, used in conjunction with your hot melt adhesive applicator, accurately controls glue output for reduced waste and more consistent output. Users can program a custom pattern with up to two glue events or simply choose the economy mode feature that automatically creates a skip of 30 or 50%. Both utilize adhesive more efficiently while still ensuring a strong bond, and the TPC-9 also gives you the flexibility to store up to 9 programs of different settings.

Overview

The TPC-9 Pattern Controller from ITW Dynatec, used in conjunction with your hot melt adhesive applicator, accurately controls glue output for reduced waste and more consistent output. Users can program a custom pattern with up to two glue events or simply choose the economy mode feature that automatically creates a skip of 30 or 50%. Both utilize adhesive more efficiently while still ensuring a strong bond, and the TPC-9 also gives you flexibility with the ability to store up to 9 programs of different settings.

Features

- Single Channel

- Test Mode for Troubleshooting/Maintenance

- Simplified "Economy Mode" feature

- Store up to 9 different program settings

The Dynatec Difference

Switch to Stitch and Save!

Replace a 6” continuous adhesive bead with a 6” skip pattern, and you cut adhesive consumption by up to 50%. It’s simple, and the savings are certain. The TPC-9 also goes the extra mile with a built-in algorithm that always ends an event with glue when using a stitch pattern so the edge is never “skipped”. Make the switch today and see the savings for yourself!

Technical data

- # of Channels: 1

- # of Programs: 9

- # of Events per Program: 2

- # of Triggers: 1

- Trigger Input Signal: NPN/PNP or contact closure

- Max Adjustable Range: 9.999 seconds per event (1 millisecond increments)

- Power Supply/Input Power: 120VAC, 50/60 Hz, L1/N/PE / 60 watts (wout output load)

- Height (H): 19 cm (8 in)

- Depth (D): 6.6 cm (2.6 in)

- Width (W): 12.5 cm (5 in)